PHOTOMATIQ®

Automated photonics manufacturing

PHOTOMATIQ® is a customizable photonics automation packaging platform for manufacturing

Flexible precise & productive automation platform for photonics

The Photomatiq is ideally suited for different photonics manufacturing product. It’s designed for the automated micro-assembly of the following products :

- Laser DPSS

- Laser diode

- Lidar

- Fiber optical connector

- Fiber to PIC coupling

- Fast AXis Colimator

- …

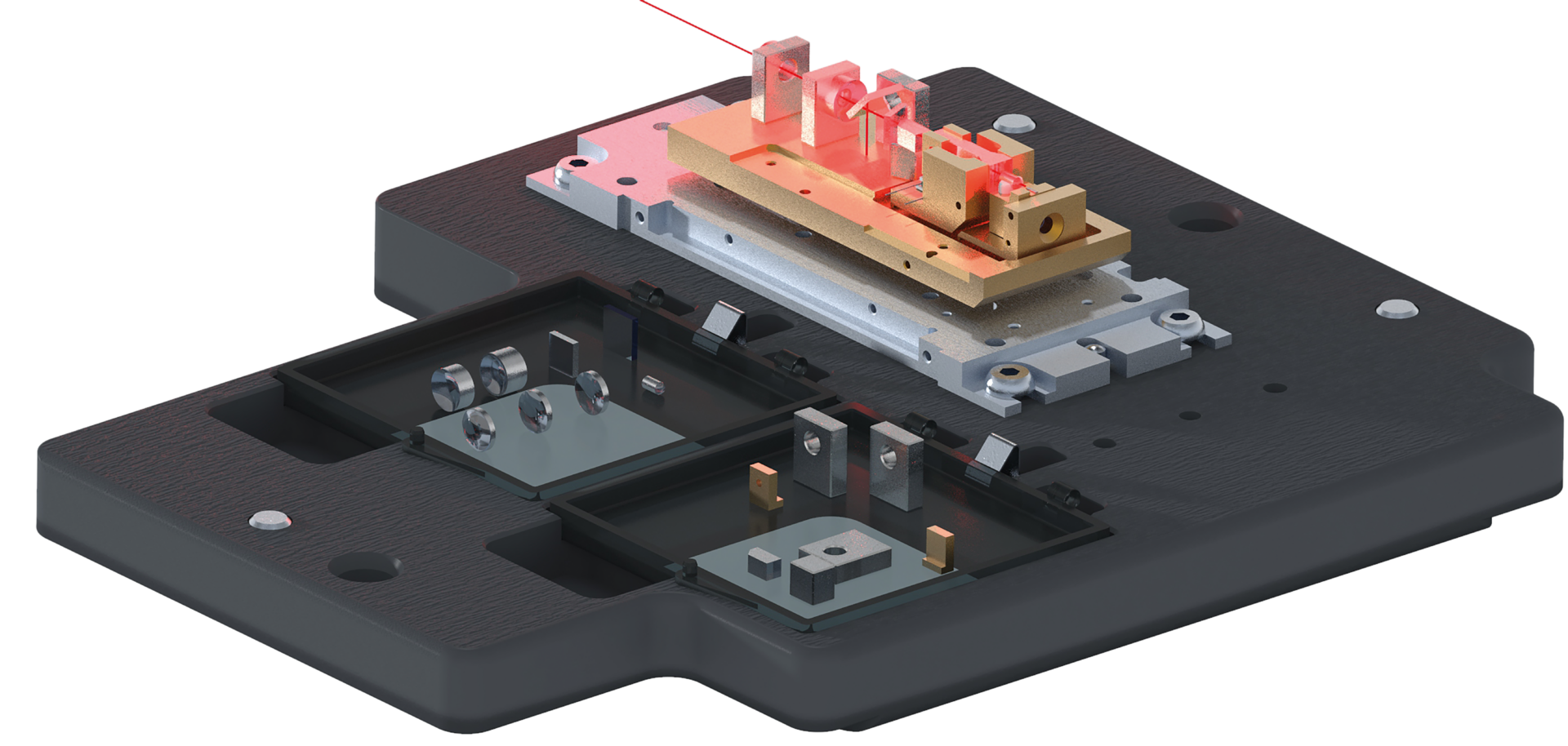

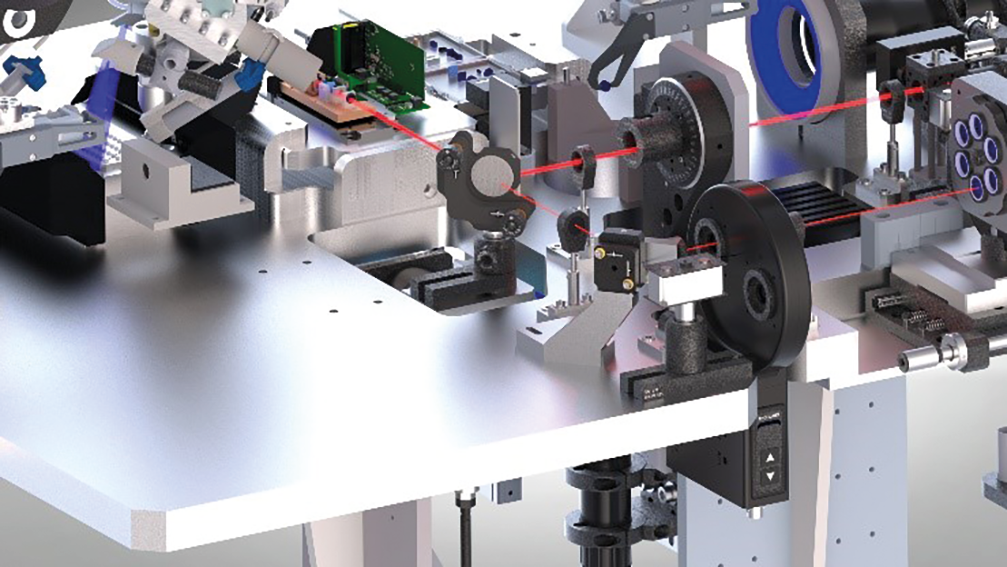

Customizable machine architecture for the photonics automation manufacturing

Common base

Customization

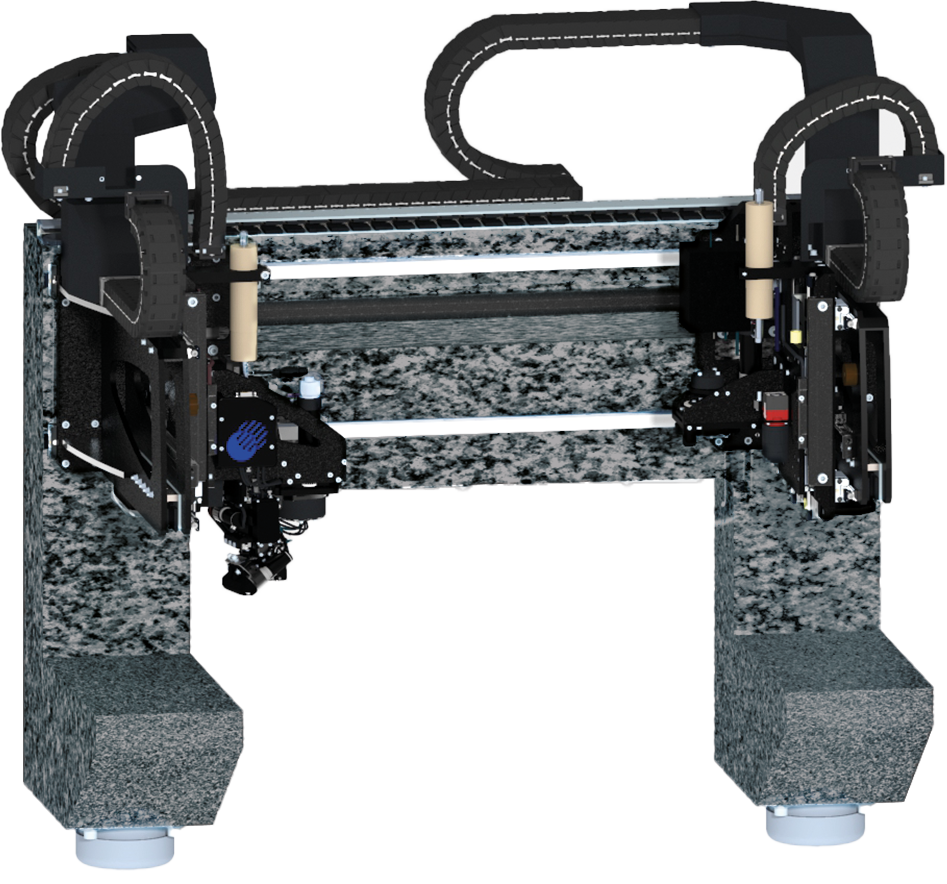

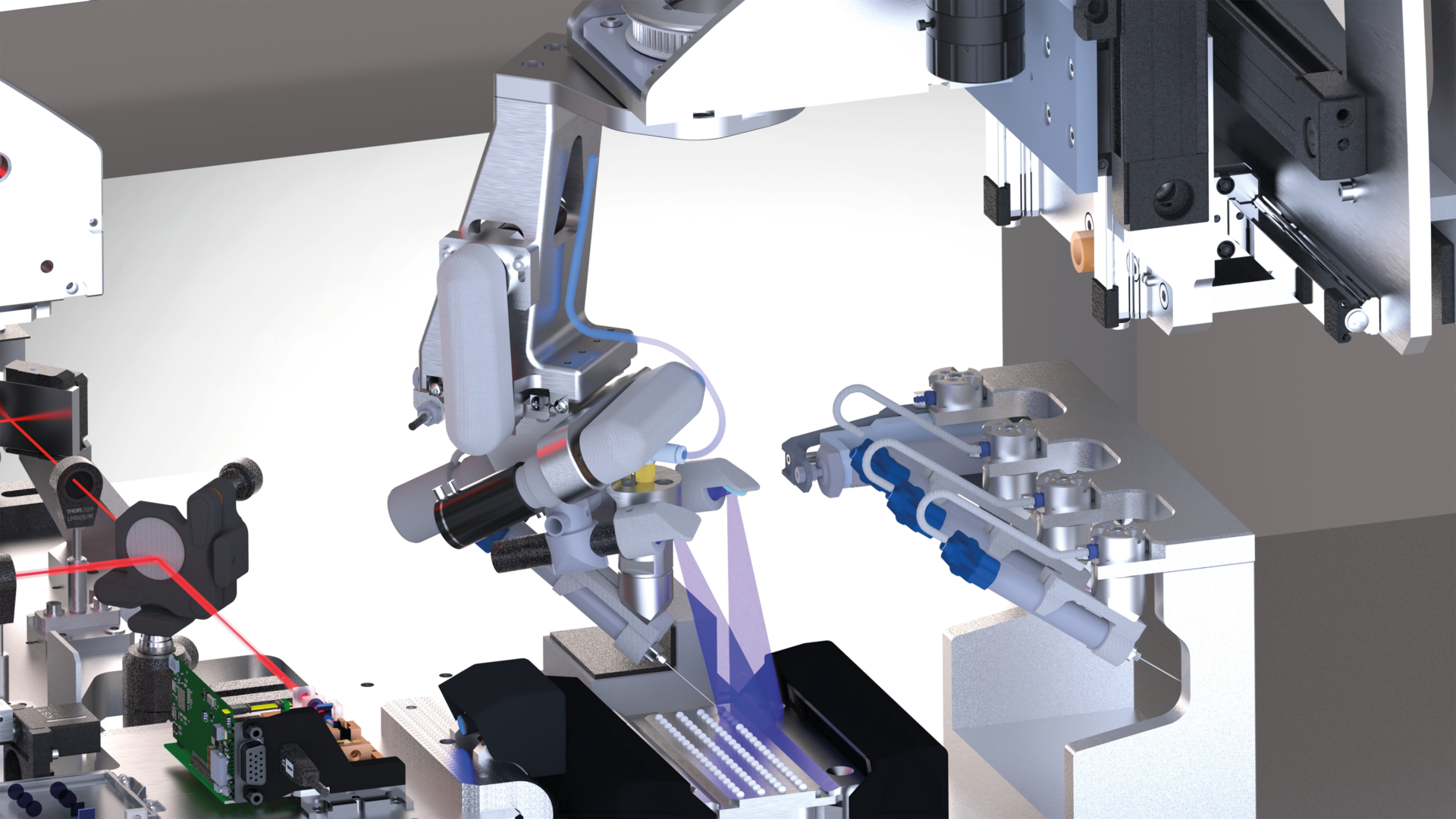

Photomatiq: two high precision robots working simultaneously for photonics application

2 robots

- X, Y, Z, Θx, Θy, Θz

- Integrated goniometer

- Resolution: 0.1 µm

Working area

- Measurement: 300 x 200 mm

- Automatic loading/unloading parts

- Granite reference surface

- High stability

- Vibration absordber

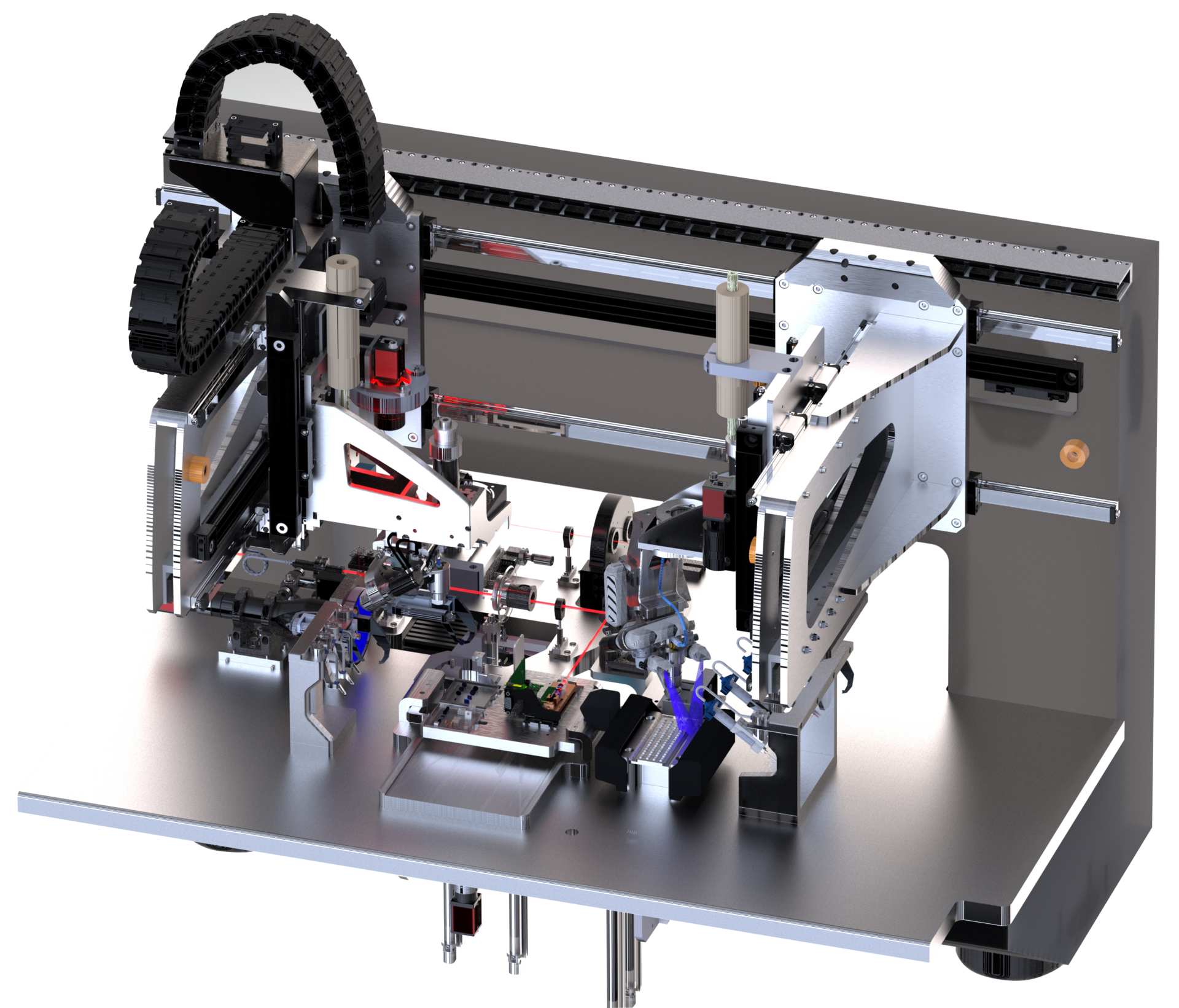

Photomatiq: photonics automation platform capabilities for manufacturing

The Photomatiq® main features are passive and active alignment as well as bonding.

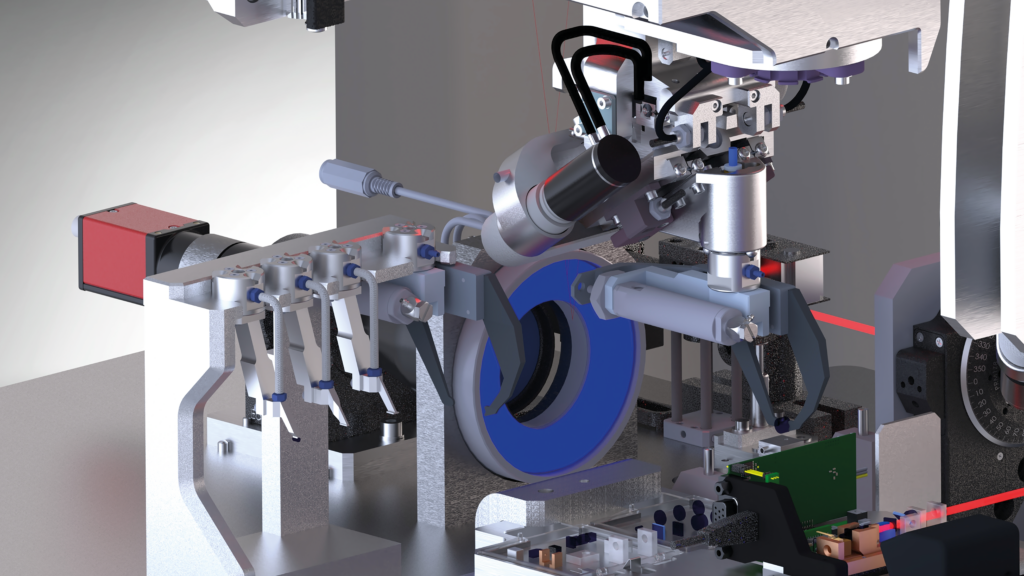

Passive alignment

In passive alignment process, the relative position and orientation between two components is evaluated and adjusted based on the camera measurements.

Active alignment

The major advantage of active alignment is achieving very high product performance, while individual components do not need to be extremely geometrically accurate.

Gluing

- Gluing in situ UV curing

- Integrated time/pressure dispenser

- Customized pattern

- Autocalibration

- Repeatable dispensing

- < 300µm cordon width

- 45° needle orientation to dispense under the components

- Alternative technologies such as jetting & dipping are also available as an option

Photomatiq proof of concept at ISP System HQ

Please feel free to contact us using the following form to know more about Photomatiq.

ISP System can propose proof of concept as well as testing session to make sure of the compatibility with your assembly process.

Contact us

Please feel free to contact us using the following form to know more about PHOTOMATIQ®.

ISP System can propose proof of concept, as well as testing session to make sure of the

compatibility with your assembly process.